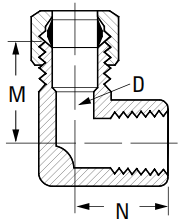

70 Female Adapter Elbow SAE # 060203BA Brass Compression Fittings 70 270C BSE3 170C

SAE 060203BA 70 270C BSE3 170C

SAE 060203BA 70 270C BSE3 170C

|

PART# |

TUBE O.D x FEMALR NPTF | N | M | D |

| 70-03-02 | 3/16×1/8 | .470 | .69 | .125 |

| 70-04-02 | 1/4×1/8 | .470 | .69 | .188 |

| 70-04-04 | 1/4×1/4 | .562 | .75 | .188 |

| 70-05-02 | 5/16×1/8 | .600 | .78 | .234 |

| 70-05-04 | 5/16×1/4 | .562 | .78 | .250 |

| 70-06-04 | 3/8×1/4 | .580 | .81 | .312 |

| 70-06-06 | 3/8×3/8 | .580 | .88 | .312 |

| 70-08-04 | 1/2×1/4 | .700 | 1.00 | .312 |

| 70-08-06 | 1/2×3/8 | .700 | 1.00 | .406 |

| 70-08-08 | 1/2×1/2 | .880 | 1.00 |

.406 |

nterchangeability for reference

Parker : 170C-2-2 170C-3-2 170C-4-2 270C-42 170C-44 170C-6-4 170C-6-6 170C-74 170C-8-6 170C-8-8 170C-12-12

Eaton/WeatherHead : 70×3 70×4 70×6 70×8

Midland : 18-251 18-252 18-253 18-253B*18-254 18-267 18-268 18-255 18-256 18-257 18-258 18-259 18-260 18-250 18-261 18-262 18-263 18-270 18-269 18-264 18-265 18-266

attention please :Quotations and delivery of non-stock items supplied on request. Configurations and dimen sions subject to change without notice. Additional information can be found in SAE J530 Automotive Pipe Fittings and SAE J531 Drain Plugs.

Brass Compression Fittings & Adapters

Applications

Compatible with copper, brass, aluminum and thermoplastic tubing for instrumentation, hydraulic and pneumatic systems like typical fluid air, oil, water, lubricant and other applications.

Note: When use with thermoplastic tubing, a brass insert is required for support.

Features

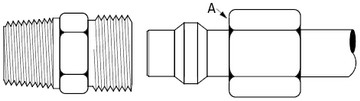

- Construction – Three piece unit: body, nut (available with long or short nut) and sleeve. Extruded and Forged Configuration.

- Vibration resistance – Fair vibration resistance with short nut, The long nut can be used for greater vibration application.

- Advantages – Low cost. Easy to assemble without special tube prep, no flaring.Broad selection of styles and sizes.

Specification

- Temperature Range: -65°F to +250°F (-53°C to +121°C) range at maximum operating pressures.

- Working Pressure: up to 2000 PSI with a 4:1 safety factor depending on tube sizes. When using plastic tubing, use the working pressure for type used.

Assembly Instructions

- Cut tubing to desired length.

- Slide nut and then sleeve on tube. Threaded end “A” of nut must face out.

- Insert tubing into fitting body. Be sure tubing is bottomed on fitting shoulder.

- Lubricate threads and assemble to fitting body.

- Tighten nut hand tight. From that point, tighten with a wrench the number of turns indicated in the chart (For Fractional Tubes) below.

|

TUBE SIZE

|

Additional Turns From Hand Tight

|

|

1/8” thru 1/4”

|

1-1/4

|

|

5/16”

|

1-3/4

|

|

3/8” thru 1”

|

2-1/4

|

US Brass Compression Fittings & Adapters

- Extruded Bar Stock, Hex Forging Blank, Fractional Tube Dia & NPT Thread Mainly.

Euro Brass Compression Fittings & Adapters

- Extruded Bar Stock, Round Forging Blank, Nickel-Plated, Metric Tube Dia & BSP Thread Mainly.